Description

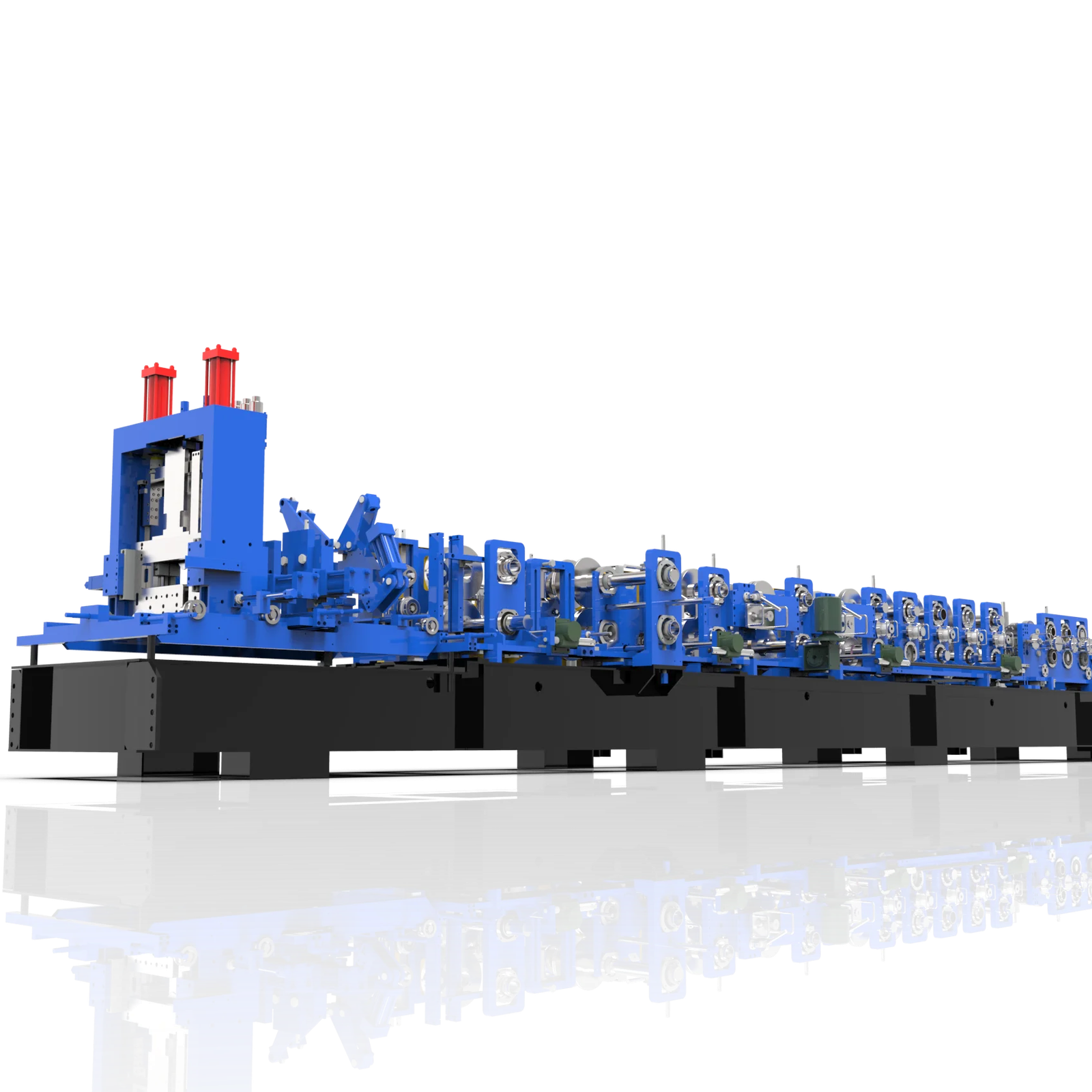

The Z Purlin Roll Forming Machine designed by Solaris Industries Ltd. is widely used in steel structures requiring high load-bearing capacity with lightweight construction. Z purlins provide excellent spanning capability and are widely installed in roofing systems of manufacturing units, warehouses, cold storage facilities, and large industrial buildings.

This heavy-duty machine features hydraulic decoiling, servo-driven feeding, precision leveling, high-strength roll forming stations, and optional punching units. The Z purlin machine can be configured as manual size-changing or automatic size-changing, depending on the customer’s budget and production needs.

Z purlins require accuracy in web width, flange height, and bending angle. Our CNC-machined rollers and solid mill stands guarantee dimensional precision and profile uniformity. The hydraulic cutting unit ensures clean, burr-free cutting with long blade life.

Production speeds range from 10–18 meters/min depending on material thickness and punching load. The PLC-based automation system simplifies operations, allowing length presetting, fault detection, and operational diagnostics.

Solaris Industries Ltd. provides customization for Z purlin dimensions, punching patterns, coil width, and structural strength requirements. With a durable frame, vibration-resistant design, and low-maintenance operation, this machine ensures long-term profitability for steel fabricators, PEB manufacturers, and solar mounting companies.

⭐ Applications:

- PEB steel structures

- Roofing sheet support systems

- Solar mounting structures

- Industrial structural framing

🔧 Technical Specifications (Z Purlin Roll Forming Machine)

| Parameter | Specification |

| Material | GI / HR / CR / Mild Steel |

| Thickness | 1.5 mm – 3.2 mm |

| Coil Width | Up to 600 mm |

| Z Purlin Sizes | 120–350 mm web width |

| Punching Unit | Optional hydraulic punch |

| Cutting System | Hydraulic shearing |

| Forming Speed | 10–18 m/min |

| Roller Material | Cr12 / SKD11 hardened steel |

| Control System | PLC + HMI touchscreen |

| Changeover | Manual or Automatic |