Description

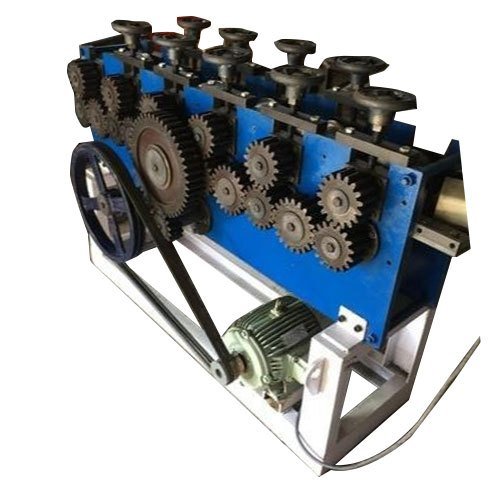

The Shutter Patti / Rolling Shutter Roll Forming Machine by Solaris Industries Ltd. is engineered to produce high-quality rolling shutter slats (patti) used in commercial shops, industrial gates, warehouses, garages, and security enclosures. Designed for consistent performance and long-term reliability, this machine ensures smooth production of shutter profiles with perfect curvature, precise interlocking, and uniform thickness.

The machine features a heavy-duty decoiler, feeding guide, roll forming stations, embossing unit (optional), and a hydraulic cutting mechanism. The forming rollers are CNC-machined from hardened steel (Cr12/D2), ensuring the slats maintain the correct overlap and interlocking structure essential for flexible rolling and long service life.

Solaris Industries Ltd. offers machines capable of producing:

- Flat shutter slats

- Curved shutter slats

- Perforated shutter slats

- Heavy-duty industrial shutter profiles

Material compatibility includes GI, CR, PPGI, and aluminum in thicknesses from 0.4 mm to 1.2 mm. The machine can achieve production speeds between 10–25 meters per minute depending on the material and profile.

The PLC touchscreen interface allows operators to set sheet length, batch quantity, and speed. Optional inline perforation units are available for ventilation-type shutters commonly used in malls and commercial buildings. The hydraulic cutting unit ensures burr-free cuts and strengthens production accuracy.

Applications include shops, showrooms, commercial shutters, industrial door systems, godowns, security barriers, and garage shutters.

🔧 Technical Specifications — Shutter Patti / Rolling Shutter Machine

| Parameter | Specification |

| Material | GI / CR / PPGI / Aluminum |

| Thickness | 0.4 – 1.2 mm |

| Coil Width | 150–400 mm |

| Profile Types | Curved, flat, perforated |

| Cutting | Hydraulic cutting |

| Speed | 10–25 m/min |

| Roller Material | Cr12 / D2 hardened steel |

| Control System | PLC + HMI |

| Optional | Perforation unit, embossing unit |