Description

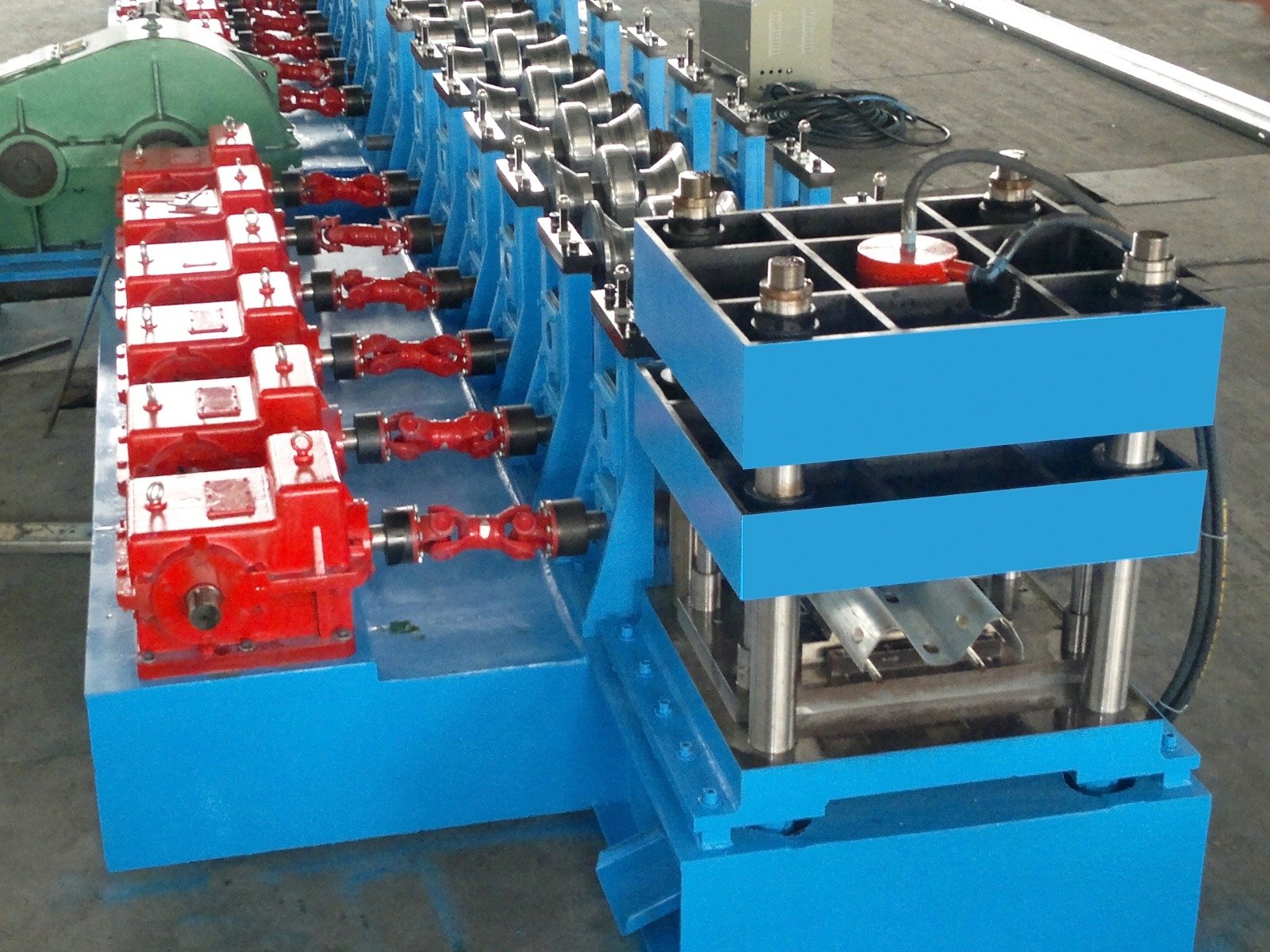

The W-Beam / Highway Guardrail Roll Forming Machine from Solaris Industries Ltd. is engineered to manufacture high-strength road safety barriers used on highways, expressways, bridges, and industrial zones. Designed for heavy-duty, continuous production, this machine produces W-beam and thrie-beam profiles that meet international road safety standards.

The production line includes:

- Hydraulic decoiler (5–10 ton)

- Leveling machine

- Servo feeder

- Heavy-duty hydraulic punching unit

- Multi-stage roll forming stations

- Hydraulic cutting system

- Automatic stacking unit (optional)

Guardrails require deep corrugation, precise hole punching, and heavy-gauge metal forming. Our punching unit uses high-strength hydraulic cylinders with specialized dies to create mounting holes, post holes, and slot patterns according to MORTH, AASHTO, or EN1317 standards.

The forming rollers are made from premium-grade hardened alloy steel designed to handle plate thicknesses from 2.5 mm to 4.2 mm. The machine operates smoothly with minimal vibration due to its robust structural framework.

The PLC control system manages length settings, punch timing, forming speed, and fault diagnosis. Production speed ranges between 8–12 meters per minute depending on material thickness and die load.

Applications include:

- National highways

- State highways

- Bridges & flyovers

- Industrial safety barriers

- Crash barrier installations

🔧 Technical Specifications — W-Beam Guardrail Roll Forming Machine

| Parameter | Specification |

| Material | GI / HR Coils |

| Thickness | 2.5 – 4.2 mm |

| Coil Width | 350–760 mm |

| Beam Type | W-Beam / Thrie-Beam |

| Punching | Heavy-duty hydraulic punching |

| Cutting | Hydraulic shear |

| Speed | 8–12 m/min |

| Roller Material | D2 / Cr12 hardened alloy |

| Control | PLC + HMI |

| Optional | Auto stacker, double-lane forming |