Description

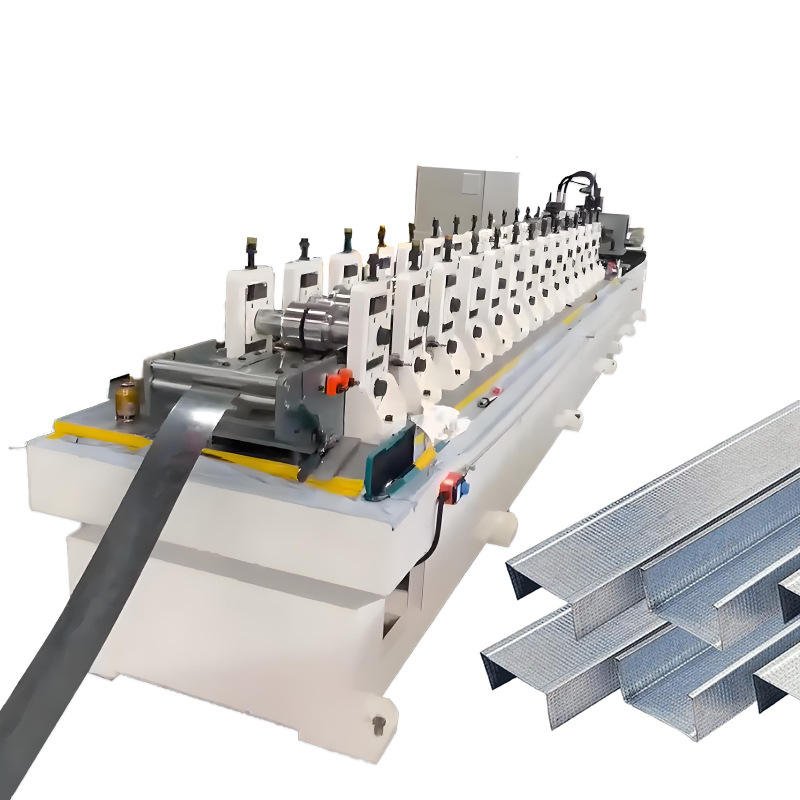

The Furring Channel Roll Forming Machine by Solaris Industries Ltd. is designed to manufacture lightweight channels used in false ceilings, drywall frameworks, wall paneling, and acoustic systems. Furring channels help provide a straight and secure mounting surface for plasterboard, ceiling sheets, and interior finishing materials.

Our machine is engineered for smooth, high-speed, and precise profile formation. It includes an automatic decoiler, feeding system, roll forming mill, hydraulic cutter, and optional punching mechanism. Each forming roller is CNC-machined and hardened to ensure consistency in shape and dimension.

The machine can produce multiple furring profiles such as 25×25 mm, 25×45 mm, 50 mm channels, and other customized shapes depending on customer requirements. Material compatibility includes GI and cold-rolled steel from 0.3 mm to 0.6 mm.

With a PLC-driven interface, operators can easily control production length, speed, and diagnostics. The machine runs vibration-free due to its strong structural design, ensuring long-term reliability and low maintenance. Production speeds can reach up to 40 meters per minute, making it a preferred choice for large-scale interior construction material manufacturers.

Applications include ceiling grids, wall furring, interior partitions, acoustic panel fixing systems, and modular room frameworks.

🔧 Technical Specifications — Furring Channel Roll Forming Machine

| Parameter | Specification |

| Material | GI / CR Steel |

| Thickness | 0.3 – 0.6 mm |

| Coil Width | 80–200 mm |

| Profile Types | 25×25, 25×45, 50 mm (customizable) |

| Speed | Up to 40 m/min |

| Cutting | Hydraulic cutting |

| Punching | Optional inline punching |

| Roller Material | Hardened tool steel |

| Control System | PLC + HMI |