Description

Roofing Sheet Roll Forming Machine – (Solaris Industries Ltd.)

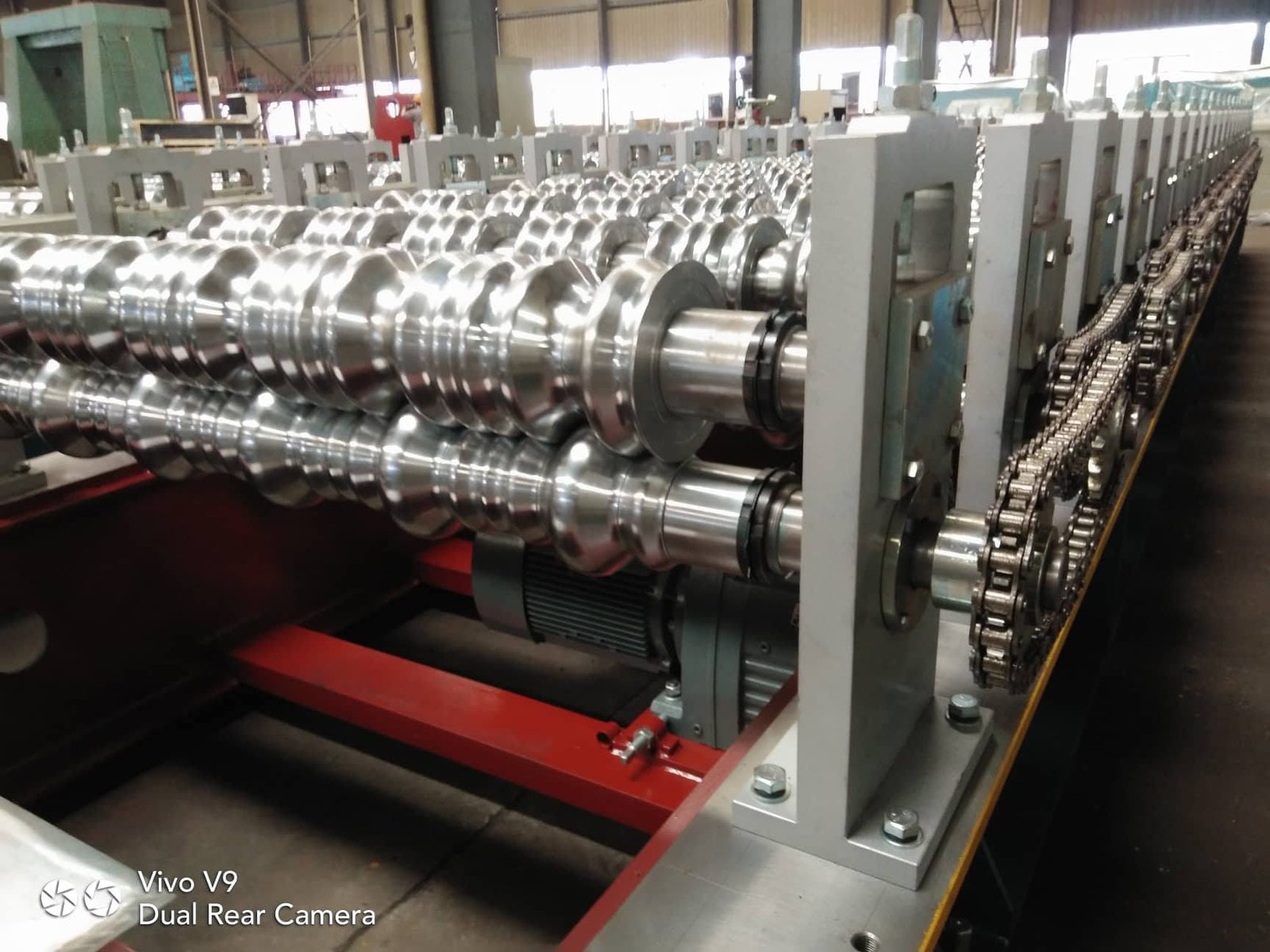

The Roofing Sheet Roll Forming Machine manufactured by Solaris Industries Ltd. is an advanced, high-performance production system engineered for manufacturing premium-quality metal roofing panels. Designed to meet the diverse needs of the construction, pre-engineered building (PEB), and infrastructure sectors, this machine ensures unmatched precision, high durability, and long-term operational efficiency.

Built on a heavy-duty welded frame, the machine offers exceptional rigidity to withstand continuous industrial production. It integrates an automatic decoiler, adjustable material feeding system, precision roll forming stations, cutting station, and PLC control system into one seamless manufacturing line. Each roll forming station is CNC-machined to achieve perfect alignment, ensuring that the roofing profiles maintain uniform rib depth, straightness, and superior surface finish.

The rollers are manufactured from hardened alloy tool steel (Cr12 / D2) and coated for wear resistance, enabling smooth sheet flow without scratches or deformities. This makes the machine suitable for producing high-quality roofing sheets from materials such as GI, PPGI, PPGL, aluminum, and stainless steel.

The machine can handle coil thicknesses ranging from 0.3 mm to 0.8 mm, and coil widths up to 1250 mm, allowing manufacturers to produce a variety of roofing designs including trapezoidal, sinusoidal, and custom ribbed profiles. With production speeds of 15 to 35 meters per minute, Solaris Industries Ltd.’s roofing sheet machine is optimized for high-volume manufacturing environments.

A hydraulic or servo-driven cutting unit ensures burr-free, distortion-free cutting with high length precision (±1 mm). The PLC touchscreen interface allows operators to automate length settings, batch production, fault diagnostics, and speed control effortlessly.

Optional add-ons include:

- Embossing rollers for texture finish

- Film lamination unit for sheet protection

- Curving / Crimping unit for arch roofing

- Automatic stacking system

With its superior engineering, low maintenance requirements, and long service life, the Roofing Sheet Roll Forming Machine from Solaris Industries Ltd. is the ideal choice for roofing sheet manufacturers, PEB companies, and infrastructure development firms looking for consistent performance and reduced operational costs.

🔧 TECHNICAL SPECIFICATIONS — Roofing Sheet Roll Forming Machine

| Parameter | Specification |

| Material Type | GI, PPGI, PPGL, Aluminum, SS |

| Material Thickness | 0.3 – 0.8 mm |

| Coil Width Capacity | 914–1250 mm |

| Decoiler Capacity | 3–5 tons (manual/hydraulic) |

| Forming Stations | 12–22 stations (as per profile) |

| Roller Material | Cr12 / D2 hardened & chrome-coated |

| Shaft Diameter | 60–75 mm (EN8 / EN9 steel) |

| Forming Speed | 15 – 35 m/min |

| Cutting System | Hydraulic or Servo cutting |

| Cutting Accuracy | ±1 mm |

| Power Requirement | 10–25 HP (based on configuration) |

| Control System | PLC + HMI Touchscreen |

| Transmission System | Chain or Gear Drive |

| ** lubrication** | Automatic / Manual oiling |

| Output Profile | Trapezoidal, Ribbed, Corrugated (custom) |

| Optional Add-ons | Embossing, Crimping, Film Laminator, Auto Stacker |